If you have ever done a home improvement project, you know the routine of getting rid of construction waste: rent a dumpster to haul off the old materials. Perhaps a simple solution for a residential project, but imagine if you are renovating an airport!

When Portland International Airport replaced 13 acres of carpet in the PDX terminal and rental car facility in 2015, Port of Portland faced a huge waste disposal problem. Thirteen acres of carpet was not only going to take a lot of dumpsters, but also fall short of the Port’s “zero waste” goals. By treating the carpet as a reusable material and collaborating with Rubenstein’s (flooring contractor), local businesses and community organizations, the PDX carpet replacement project found alternative uses to extend the useful life of materials that may have been otherwise sent to a landfill. In fact, the project recently received Gold in the 18th Annual Starnet Design Awards for environmental achievement.

Five Years to Zero Waste (2014) is the Port’s ambitious plan to achieve the actions necessary to reach “zero waste” status, defined as waste diversion of 90% or greater. Meeting the goals of this framework is an ongoing challenge – especially when faced with large construction projects.

The Port’s Environmental Management System creates a framework to evaluate each new project so as to minimize environmental impacts and apply the latest innovations in design and execution. Project specifications include, energy-efficient lighting or plumbing fixtures that conserve water. In some cases it is an innovation in process, not necessarily technology that produces sustainable outcomes.

In the carpet replacement project, the Port’s Request for Proposal (RFP) prioritized a requirement for the contractor to find a more sustainable option than sending the old carpet to the landfill. The Port suggested disposing of the carpet at a waste to energy (WTE) facility because of limited recycling options available; however, the RFP was written with flexibility to allow contractors to find alternative outlets.

Just before the PDX carpet replacement project began, the airport carpet frenzy grew amongst Portlanders. The flying public and Portland community had become attached to the unique carpet installed nearly 30 years ago. Its iconic design began showing up on socks, t-shirts, and shoes and the media noticed. Stories about the PDX carpet appeared in local, national and even international publications. PDX Carpet was even the Grand Marshall of the 2015 Rose Parade!

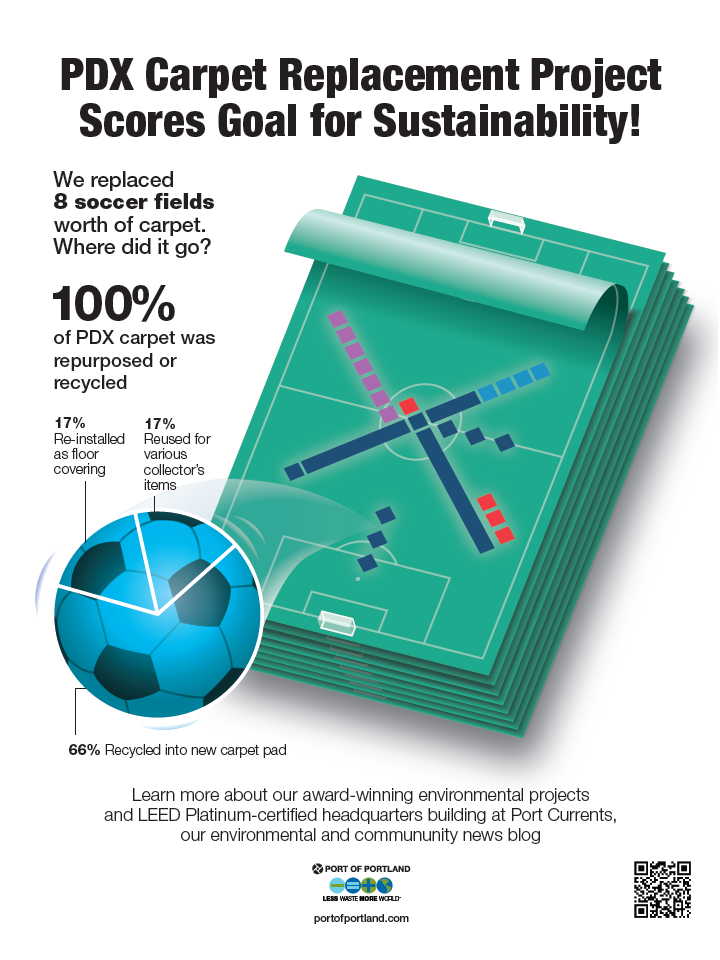

Recognizing the high public interest, the Port evaluated proposals from interested businesses based on their proposed use and community benefit to reuse the carpet. The Port’s selected flooring contractor, Rubenstein’s, developed a technique to remove the carpet in larger intact pieces which were then inventoried based on condition and distributed to selected businesses. In total, nearly 5 acres of carpet was installed in buildings throughout the region, used in high school batting cages, repurposed into a variety of novelty products or became furniture upholstery.

At the end of the project, eight acres of carpet remained for disposal. With the growing attention, Rubenstein’s sought a more sustainable disposal option for the remaining carpet than incineration at a WTE. They found a facility in California that reuses carpet fibers to make carpet pad. By sending the remaining PDX carpet to this facility they ensured 100% of the carpet from the project was repurposed or recycled.

Rubenstein’s further embraced the Port’s commitment to minimizing waste by also diverting construction debris from the project. Cardboard cores from the new carpet rolls were given to a local carpet warehouse to reuse, pallets were returned to suppliers, artisans used wood from broken pallets to make furniture and art pieces, and all plastic film was recycled.

The PDX carpet replacement project demonstrates how integrating waste minimization strategies into project planning can benefit the community and do not necessarily interfere with the project schedule or increase costs. Integrating sustainability goals into contract specifications and taking time to work with stakeholders for reuse options are strategies that can be applied in a wide variety of construction projects – large and small.